公司新闻

联系我们

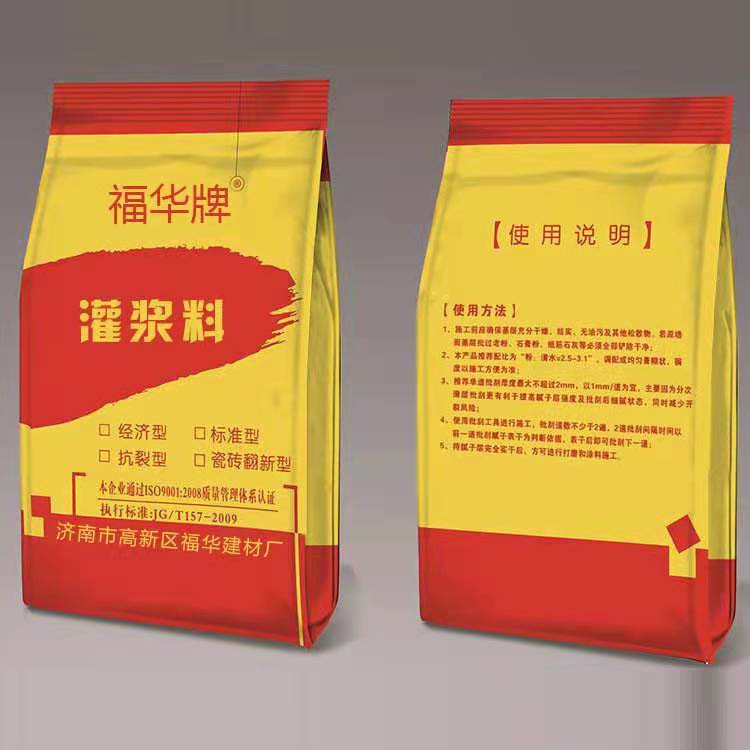

济南福华建材厂

联系人:吴老师

电话:13864111871

手机:13864111871

0531-81901300

地址:山东省济南市高新开发区巨野河办事处山圈村西

济南石膏粉按不同的特点分哪些类?

来源:https://www.jnfhjc.com 日期:2019-07-12 发布人:

石膏粉按物理成分的不同可分为磷石膏粉、脱硫石膏粉、柠檬酸石膏粉和氟石膏粉。

Gypsum powder can be divided into phosphogypsum powder, desulfurization gypsum powder, citric acid gypsum powder and fluorine gypsum powder according to its physical composition.

石膏粉根据颜色不同可分为:红石膏粉、黄石膏粉、绿石膏粉、绿石膏粉、白石粉、蓝石膏粉、彩色石膏粉。

Gypsum powder can be divided into red gypsum powder, yellow gypsum powder, green gypsum powder, green gypsum powder, white gypsum powder, blue gypsum powder and color gypsum powder.

石膏粉根据不同的物理特性可分为:白云石石膏粉、粘土石膏粉、绿泥石石膏粉、石膏石膏粉、滑石粉、含砂石膏粉和纤维石膏粉。

Gypsum powder can be divided into dolomite gypsum powder, clay gypsum powder, chlorite gypsum powder, gypsum powder, talcum powder, sand gypsum powder and fibre gypsum powder according to different physical characteristics.

石膏粉按用途可分为:建材用石膏粉、化工用石膏粉、模具用石膏粉、食品用石膏粉和铸造用石膏粉等。

Gypsum powder can be divided into building material gypsum powder, chemical gypsum powder, mould gypsum powder, food gypsum powder and foundry gypsum powder.

石膏的应用历史悠久,但在早期只是简单地用来制作粉笔、腻子、豆腐和简单的工艺品,缺乏深入的研究和开发,因此没有引起人们的重视。1970年代末,特别是改革开放的实施在中国,随着经济的快速发展,大量的建筑、建筑材料和其他相关行业消费石膏需求大幅增加,石膏引起越来越多的关注,形成了一个巨大的新兴产业。

Gypsum has a long history of application, but in the early stage it was simply used to make chalk, putty, tofu and simple handicraft, lacking in-depth research and development, so it did not attract people's attention. At the end of 1970s, especially with the implementation of reform and opening up in China, with the rapid economic development, a large number of construction, building materials and other related industries consume gypsum, which attracts more and more attention and forms a huge emerging industry.

我国天然石膏矿产资源丰富,总储量近600亿吨,居世界首位,也是化工石膏的主要生产国。每年生产大量的化工石膏:每年只有磷石膏多达近2000万吨,磷肥的一部分植物磷石膏积累量高达数千万吨,特别是我国经济的快速发展和环境保护的关注,近年来,电厂脱硫过程,发电厂必须产生大量的脱硫石膏,除柠檬酸石膏、氟石膏、盐和其他化学石膏,依托丰富的自然资源和人力资源对石膏行业进行综合利用和发展,也是建设循环经济的需要,也是众多投资者的新亮点。

China is rich in natural gypsum mineral resources, with a total reserves of nearly 60 billion tons, ranking first in the world, and is also a major producer of chemical gypsum. A large amount of chemical gypsum is produced every year: only phosphogypsum reaches nearly 20 million tons every year, and the accumulation of phosphogypsum in some plants of phosphorus fertilizer reaches tens of millions of tons. Especially with the rapid economic development and the concern of environmental protection in our country, in recent years, during the desulfurization process of power plants, a large number of desulfurization gypsum must be produced to remove citric acid gypsum and fluorogypsum. Salt and other chemical gypsum, relying on abundant natural resources and human resources to comprehensively utilize and develop the gypsum industry, is also the need to build a circular economy, but also a new bright spot for many investors.

近年来,伴随石膏产品行业的发展,石膏粉的各种不同的使用也得到提升,尤其是在建筑材料行业,随着高层建筑的不断增加和国家墙改变工作的逐步深入,石膏粉已成为紧器用建材市场的产物。2005年,全国石膏粉消费量约1200万吨,产量8500万吨,缺口3500万吨,远远不能满足市场需求,因此该项目的加工开发具有较大的市场,利润高,经济效益好。

In recent years, with the development of gypsum products industry, various uses of gypsum powder have been improved, especially in the construction materials industry. With the increasing of high-rise buildings and the gradual deepening of the national wall change work, gypsum powder has become the product of the construction materials market for tighteners. In 2005, the national consumption of gypsum powder was about 12 million tons, the output was 85 million tons, and the gap was 35 million tons, which could not meet the market demand. Therefore, the processing and development of this project has a large market, high profits and good economic benefits.

目前,石膏粉生产工艺及生产线自动化水平不高,大多处于手工操作或半自动水平,济南石膏粉产品质量处于低水平、低质量状态。我厂采用立磨、泡窑等先进设备,整条生产线采用DCS自动控制系统,实现了真正的自动化生产工艺。产品质量上乘,性能优良,深受市场欢迎,更多产品需求可以点击:https://www.jnfhjc.com/

At present, the automation level of production process and production line of gypsum powder is not high, most of them are in manual operation or semi-automatic level, and the quality of gypsum powder is in a low level and low quality state. Our factory adopts advanced equipment such as vertical mill and kiln. The whole production line adopts DCS automatic control system, which realizes the real automatic production process. The product quality is excellent, the performance is excellent, and it is very popular in the market. More products can be clicked on: https://www.jnfhjc.com./

鲁公网安备

鲁公网安备