济南腻子粉和硅藻泥的环保性对比解析:从原料到应用的全维度考量

来源:https://www.jnfhjc.com 日期:2025-06-05 发布人:

在室内装修材料选择中,环保性能已成为消费者关注的核心指标。腻子粉与硅藻泥作为墙面基层处理与装饰的常用材料,其环保性差异需从原料构成、生产流程、使用场景及健康影响等多维度进行综合评估。

In the selection of indoor decoration materials, environmental performance has become a core indicator of consumer concern. Putty powder and diatomaceous earth are commonly used materials for wall base treatment and decoration, and their environmental differences need to be comprehensively evaluated from multiple dimensions such as raw material composition, production process, usage scenarios, and health impacts.

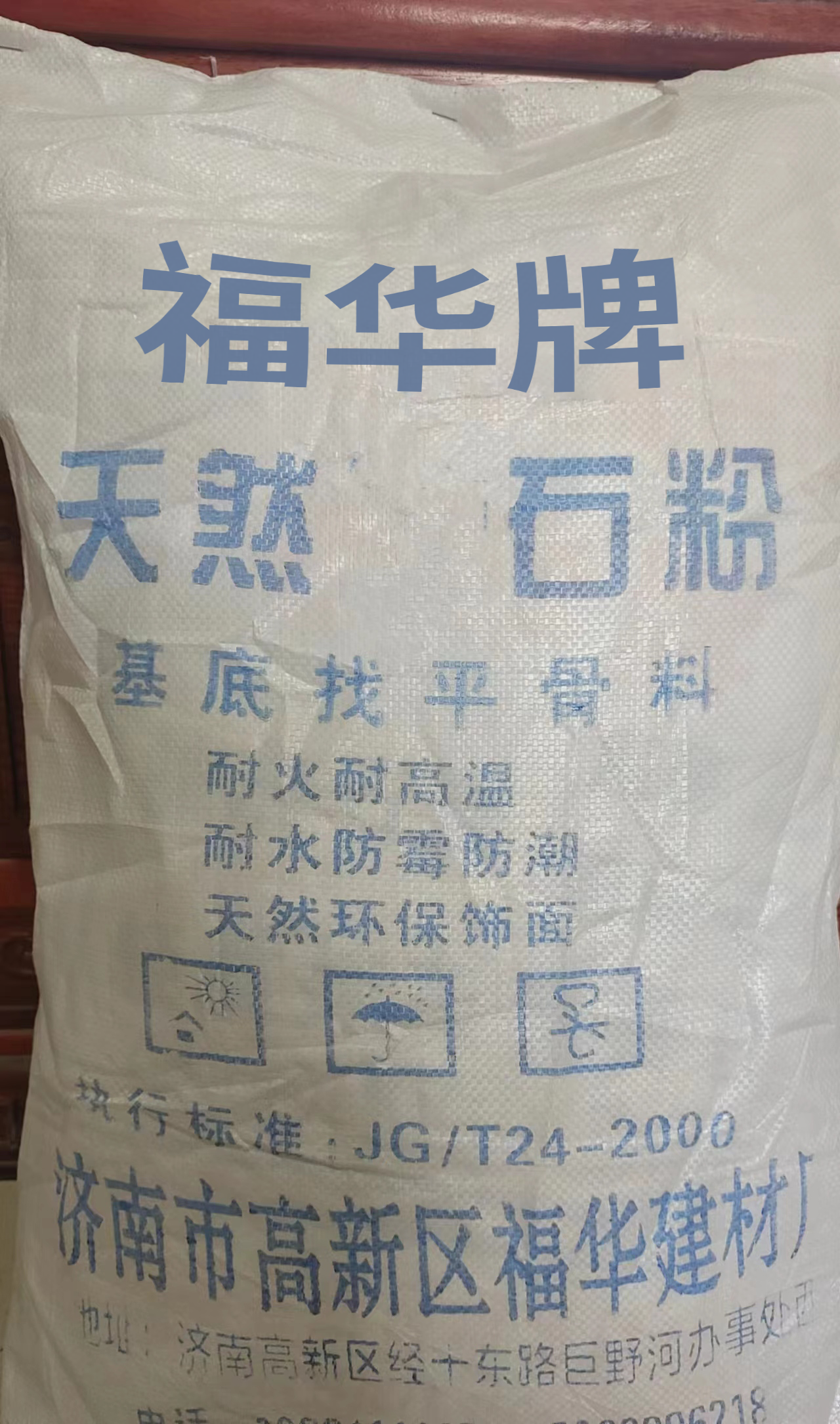

原料成分是环保性的基础决定因素。传统腻子粉以碳酸钙、滑石粉等无机矿物粉料为主体,添加纤维素醚、淀粉醚等天然或改性植物胶作为粘结剂,部分产品会加入灰钙粉提升硬度。这类配方中,重金属含量通常低于国家强制标准,但低端产品可能因使用劣质胶粉导致甲醛残留。硅藻泥则以硅藻土为核心原料,其多孔结构赋予材料调节湿度的功能,但需配合石英砂、粘土及化学助剂改善施工性能。值得注意的是,部分硅藻泥产品为提升粘结力会添加白水泥或石膏,可能引入微量放射性物质,需通过权威检测确保氡浓度达标。

The composition of raw materials is the fundamental determinant of environmental friendliness. Traditional putty powder is mainly composed of inorganic mineral powders such as calcium carbonate and talcum powder, with the addition of natural or modified plant adhesives such as cellulose ether and starch ether as binders. Some products also add calcium ash powder to enhance hardness. In this type of formula, the heavy metal content is usually lower than the national mandatory standard, but low-end products may have residual formaldehyde due to the use of inferior rubber powder. Diatomaceous earth is the core material of diatomaceous earth, and its porous structure endows the material with the function of regulating humidity, but it needs to be combined with quartz sand, clay, and chemical additives to improve construction performance. It is worth noting that some diatomaceous earth products may add white cement or gypsum to enhance adhesion, which may introduce trace amounts of radioactive substances. Authoritative testing is required to ensure that radon concentration meets the standard.

生产环节的环保控制直接影响最终产品的绿色属性。正规腻子粉工厂采用全封闭自动化生产线,粉尘排放通过布袋除尘器处理,废水经沉淀池循环利用,但小型作坊可能因工艺落后造成扬尘污染。硅藻泥生产对原料研磨精度要求更高,能耗较普通腻子粉生产增加约20%,但部分企业通过余热回收技术降低能耗。两类材料在烘干环节均存在能源消耗差异,电加热与天然气烘干对碳排放的影响需纳入环保评估体系。

The environmental control in the production process directly affects the green attributes of the final product. Legitimate putty powder factories adopt fully enclosed automated production lines, with dust emissions treated through bag filters and wastewater recycled through sedimentation tanks. However, small workshops may cause dust pollution due to outdated processes. The production of diatomaceous earth requires higher grinding accuracy for raw materials, and the energy consumption is about 20% higher than that of ordinary putty powder production. However, some enterprises reduce energy consumption through waste heat recovery technology. There is a difference in energy consumption between the two types of materials in the drying process, and the impact of electric heating and natural gas drying on carbon emissions needs to be included in the environmental assessment system.

使用阶段的健康风险是消费者最直接的关切点。腻子粉施工需与胶水混合,劣质胶水中的甲醛释放周期可达3-15年,成为室内空气污染主要来源。而硅藻泥采用干粉兑水搅拌,施工过程无需添加有机溶剂,理论上可避免VOC释放。但硅藻泥的多孔结构可能吸附空气中的游离甲醛,需关注其分解能力——仅添加光触媒或纳米二氧化钛的产品才具备持续净化功能,普通硅藻泥仅起物理吸附作用。

The health risks during the usage phase are the most direct concern for consumers. Putty powder construction needs to be mixed with glue, and the formaldehyde release cycle in inferior glue can reach 3-15 years, becoming the main source of indoor air pollution. Diatom mud is mixed with dry powder and water, and there is no need to add organic solvents during the construction process, theoretically avoiding VOC emissions. However, the porous structure of diatomaceous earth may adsorb free formaldehyde in the air, and its decomposition ability needs to be considered - only products with added photocatalysts or nano titanium dioxide have continuous purification function, while ordinary diatomaceous earth only has physical adsorption effect.

功能特性带来的环境效益不容忽视。硅藻泥的调湿性能可将室内湿度维持在40%-70%的舒适区间,减少空调除湿能耗,经测算可使建筑整体节能率提升8%-12%。其呼吸功能还能缓解墙面结露现象,延长装修寿命。腻子粉虽不具备主动调湿能力,但现代产品通过添加竹炭、海泡石等成分,也可实现一定的甲醛吸附功能,且耐水腻子在潮湿环境中的稳定性优于普通硅藻泥。

The environmental benefits brought by functional features cannot be ignored. The moisture regulating performance of diatomaceous earth can maintain indoor humidity within a comfortable range of 40% -70%, reduce air conditioning dehumidification energy consumption, and is estimated to increase the overall energy efficiency of buildings by 8% -12%. Its respiratory function can also alleviate wall condensation and extend the lifespan of decoration. Although putty powder does not have the ability to actively adjust humidity, modern products can also achieve a certain formaldehyde adsorption function by adding components such as bamboo charcoal and sepiolite, and the stability of water-resistant putty in humid environments is better than that of ordinary diatomaceous earth.

全生命周期的环保性评估需考虑材料可回收性。腻子粉作为基层材料,翻新时需完全铲除,产生建筑垃圾,但部分企业已开发可降解型产品,废弃物经破碎后可用作路基填料。硅藻泥墙面翻新可局部修补,减少材料浪费,且硅藻土本身为天然矿物,废弃后不会对土壤造成污染。

The environmental assessment of the entire lifecycle should consider the recyclability of materials. Putty powder, as a base material, needs to be completely removed during renovation, generating construction waste. However, some companies have developed biodegradable products, and the waste can be used as roadbed filling after being crushed. The renovation of diatomaceous earth walls can be partially repaired to reduce material waste, and diatomaceous earth itself is a natural mineral that will not cause soil pollution after disposal.

本文由济南腻子粉友情奉献.更多有关的知识请点击:http://www.jnfhjc.com真诚的态度.为您提供为全面的服务.更多有关的知识我们将会陆续向大家奉献.敬请期待.

This article is a friendly contribution from Jinan gypsum powder For more information, please click: http://www.jnfhjc.com Sincere attitude To provide you with comprehensive services We will gradually contribute more relevant knowledge to everyone Coming soon.

鲁公网安备

鲁公网安备